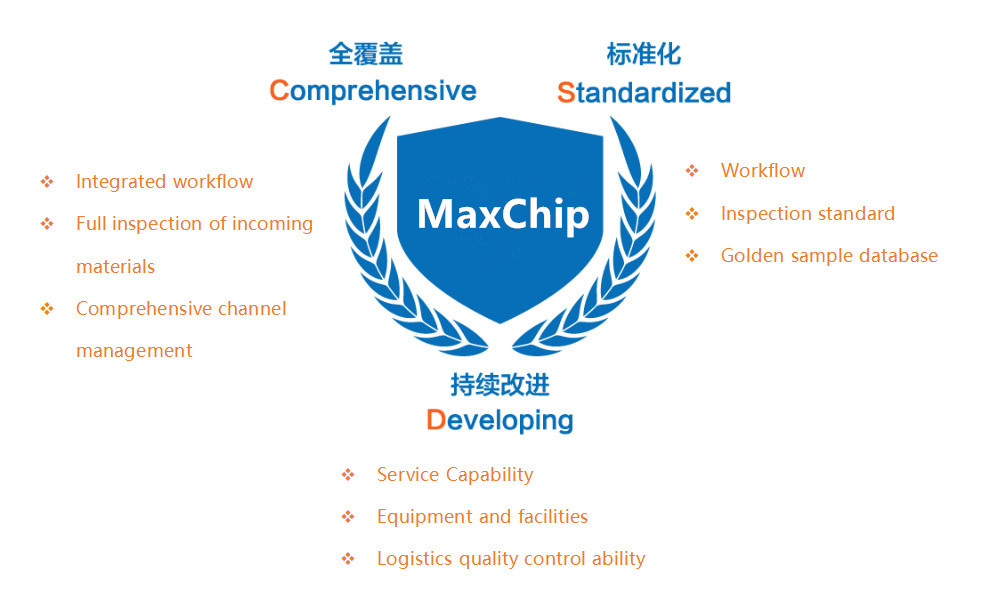

Quality Assurance

Supplier Management

With big data of ERP systerm, we classify our suppliers into 4 levels: Core Suppliers/ Qualified Supplier/ RiskySuppliers/ Blacklisted Suppliers.

We control our procurement strictly from the source.

Our Quality Assurance Center

Maxchip has a complete set of incoming components inspection process, a team of 30+ highly experienced SQE supplier quality engineer is at the helm,giving our best in quality control and testing services. We abides by international and industry testing standards strictly,and has an big database for in spection and comparison with 100,000+ sample gold data to escort your components.We are committed that there is no counterfeit to reach our customers.

3-tier International Standards QC Process

Tier 1: Labelling and packing verification

Tier 2: Advanced inspection and electrical testing

Tier 3: Foxconn/Whitehorse inspection and analysis

Reference Inspection Standard

●IPC/JEDEC Solid Stare Technology Association Standard

●GB/T2828.1-2012 National Sampling Standard

●IDEA-STD-1010-B Independent Distributors Alliance Electrobuc Components Quality Inspection Standard

●MIL-STD-883 Test Methods and Procedures for Microelectronic Devices

●ISO9001 standard

●Customer requirements

●Specifications

●Golden sample database

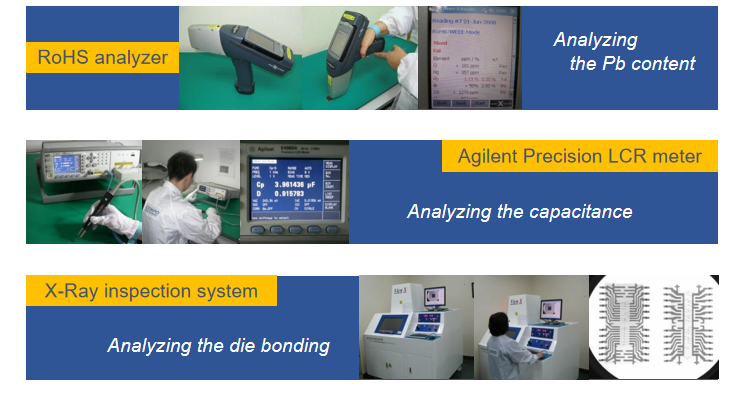

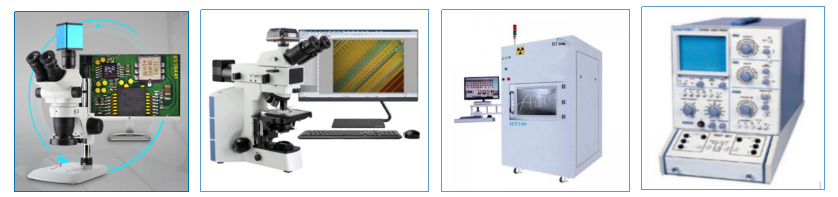

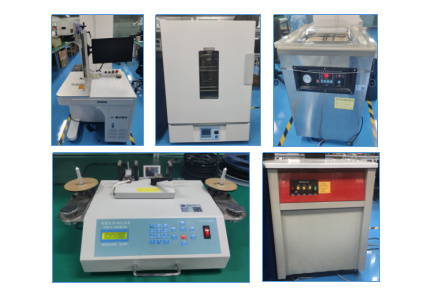

Testing Equipment

We are also the strategic partnership with Foxconn/Whitehorse Test Center

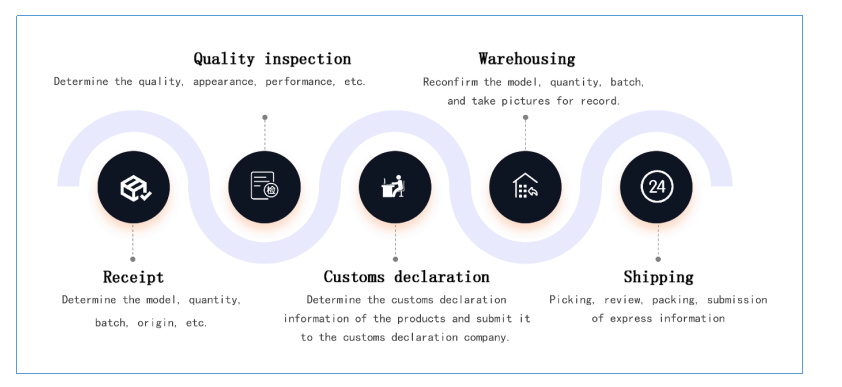

Warehousing & Packaging

We have 1000㎡ storaging warehouse and 6S standard throughout the whole process,ESD protection management , in line with ISO management standards,365days 24hours to ensure safety.

Packaging Rules

Every poduct is packed and handled in strict accordance with the packaging specifications for electronic components.It is also equipped

with vacumming machine,oven,SMT counting machine,stapping machine and laser marking machine to ensure that the packaging meets

the requirements of the industry.

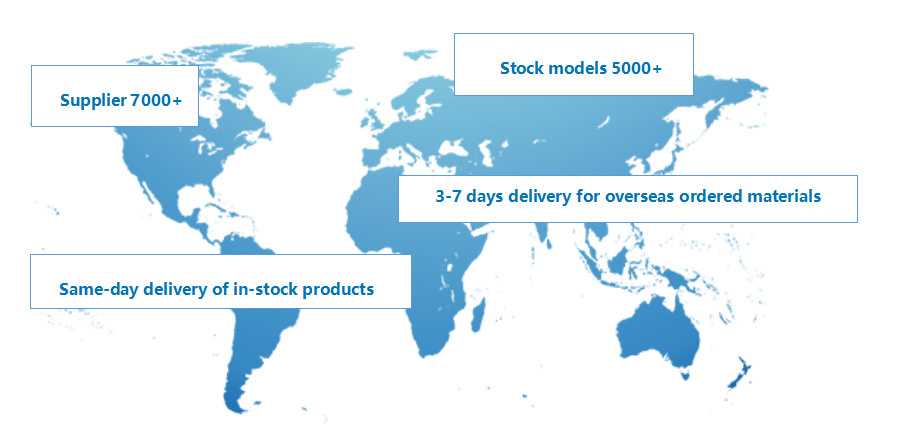

Logistics & Delivery

Delivery Time

Transport Safety

Afer-sales Service& Warranty